User-friendly, integrated Manufacturing ERP for all modes

Built with manufacturers in mind, Acumatica is a multi-site, comprehensive cloud manufacturing control and planning system

Built for today’s manufacturing challenges, Acumatica ERP is designed for agility and growth.

Razor-thin margins, less-than-ideal warehouse ops, disconnected systems and today’s unpredictable supply chain make manufacturing more challenging than ever. Enter: Acumatica Manufacturing Edition, an end-to-end manufacturing ERP that handles any mode of manufacturing with intelligent inventory controls and real-time shop floor data. AI & ML help you automate, streamline and improve your efficiency.

With hundreds of successful manufacturing projects under our belt, we’ve had the chance to really get to know the industry inside and out. We understand what makes a difference and what truly moves the needle for you. The Answer Company’s dedicated Implementation teams don’t just stop at understanding the future of manufacturing–we’re here to help you build it.

Successful Manufacturing ERP Projects

“The Answer Company set our expectations for the process and then met every one of them. Our consultant was approachable, knowledgeable, up-front, and confident in their ability to solve our challenges. We knew we were in good hands.”

— Laurie Lautenslager, CPA, Clover Leaf Cheese

Why choose Acumatica ERP?

Across decades and hundreds of projects, we’ve seen how resilient the manufacturing industry is – and how competitive. The key to success? Shedding inefficiencies, tackling issues head-on, and finding the right solutions. With the right technology in place, there’s no challenge you can’t overcome:

Managing inventory in a manufacturing environment is a balancing act. Too much stock ties up capital, while too little can halt production and disappoint customers. Without the right tools, forecasting demand, tracking materials, and ensuring timely procurement becomes a complex and error-prone process that can lead to costly inefficiencies and delays.

Master your inventory with Acumatica’s Material Requirements Planning (MRP) capabilities. The intelligent MRP system automates the entire process, providing real-time visibility into your inventory levels, forecasting needs, and optimizing order schedules. With Acumatica, you can maintain just the right amount of inventory, reduce carrying costs, and ensure that your production lines never miss a beat.

Keeping up with an unpredictable supply chain can feel like a never-ending race. The constant disruptions make it hard to plan ahead and stay competitive.

Real-time visibility and intelligent insights help you spot and fix disruptions before they become bigger issues. Advanced inventory tools give you a crystal-clear view of exactly where you stand. Plus, automated purchasing based on up-to-date demand forecasts and inventory levels means you can keep your profits intact and your operations running smoothly.

Keeping up with ever-changing regulations is no small feat. Maintaining compliance, traceability, and audit documents is tedious and unorganized.

Let Acumatica handle the paperwork. Automate your document management and reporting to meet every industry requirement with ease.Track both raw materials and finished products through the entire production process, making sure you’re compliant with safety and quality standards.

Erratic and disrupted supply chains means cost controls are inconsistent and margins are being cannibalized.

As a single source of truth, your ERP combines financial data with production data to give you up-to-date figures on costs, as they happen, helping you identify areas for savings. Intelligently optimize your inventory, labor, and production schedules to slash costs while boosting efficiency.

Finding and keeping skilled workers is tougher than ever, thanks to the ongoing labor shortage in manufacturing.

Streamline HR and workforce management with advanced scheduling to keep your shop floors fully staffed. By automating routine processes, you’ll cut down on the tedium, and boost accuracy, leading to better employee satisfaction.

Features of the ERP for Manufacturing

Manufacturers have fairly rigid requirements when it comes to an ERP. It must handle all aspects of the business, as well as integrate with any other software you already use. With an award-winning, user-friendly interface, Acumatica’s Manufacturing ERP features:

Acumatica ERP has advanced options for production planning and scheduling with user-friendly visual scheduling boards to help you manage materials, shop capacity, workforce allocation and tooling. Maximised production capacity means an accurate seamless delivery for your customers and optimised resource utilization for you.

Make warehouse management a breeze with advanced inventory control, automated replenishment, end-to-end raw materials tracking, and integration with your shop floor MRP data – across as many warehouses as you need. Integrate barcoding, matrix item management and handheld inventory management modules to digitize your entire warehouse.

Integrated shop floor management gives you real-time control of everything happening in the shop, letting you monitor and identify bottlenecks or solve problems before they grind your ops to a halt. Seamless mobile access and automation handling the tedious data entry tasks, your happier warehouse team can feel more fulfilled and more productive.

Ensure you’re meeting your compliance requirements while producing high-quality products with streamlined QC workflows, full-shop integration of data, and compliance reports out of the box. Avoid penalties for non-compliance with compliance-by-default document management. This means your products meet regulators requirements and your high standards.

Grab the reins of your costs with deep insights, real-time cost information and optimized warehouse processes. Integrate all of your cost areas to see holistic, real-time costs and to forecast for future disruption. Shift from reactive to proactive cost management with forward-thinking tools arming you for financial agility.

From purchase to packaging & shipping, Acumatica Manufacturing ERP is your supply chain management hub. Ease the friction in your supply chain with diligent supplier relationship management, automated procurement processes, inventory analysis and streamlined shipping.

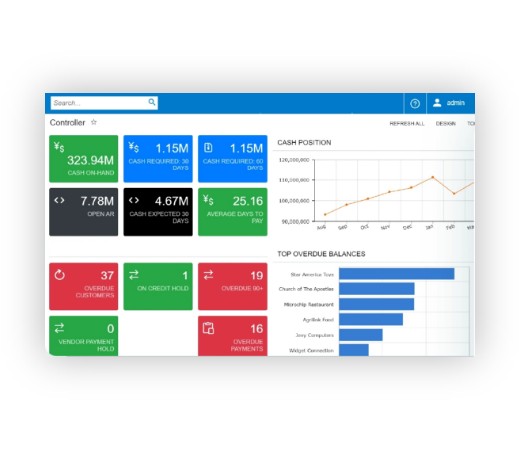

Collate all of your data in one place and use that database as the central brain for your organization. Dive into template or custom reports, tailored to what exactly you need to track: key performance indicators tied to your organizational goals. Dashboards and reports bring real-time decision-fuel to relevant team members to identify trends.

Acumatica is built on an open foundation that makes it easy to create and maintain connectors, integrations and tailored solutions to build our your ideal technology stack. The Answer Company is a leading builder of tailored and purpose-developed Acumatica integrations.

Customer Success Story

Faster Order Integration

Reduction in order entry time

Less paper used

What HERD have to say about Manufacturing Success with Acumatica:

“It is completely web-based and modern, and covered our sales and marketing needs. We also really liked that there is so much documentation; other platforms over-promised but Acumatica provided a lot of evidence that it could do what it said it would do. They put a lot of thought into serving the customer, that was evident.”

— Robert Vandenbyllaardt, CIO and CFO of Herd North America

When you find a solution you love, moving away from it is the furthest thing form your mind. Seamless integration between your existing systems and your ERP core is possible, meaning you retain what you want while still placing Acumatica at the business core, your 360° business view.

Still looking for a solution? There are hundreds of certified integrations and connectors on Acumatica Marketplace. Built on the Acumatica Platform (xRP), they stay up-to-date and fit easily within the full manufacturing ERP system.

Our team of Acumatica Platform developers think in xRP: their deep familiarity with the architecture means they understand how to bridge the gaps between the out-of-the-box solution and the ideal state of work for our clients.

From tweaked reports and field name changes to full app builds, our team brings a creative flair to their technical knowledge, giving us a dimensionality that allows us to solve problems creatively. The team has a stack of certifications and Acumatica awards for their skills.

Acumatica may be user-friendly and intuitive, but it by no means simple. The powerful manufacturing ERP functions like a central brain for your business. We’ve gathered some information that you might find useful on your search for digital transformation. No details needed, download instantly!